Combustion Research Unit - CRU

The Ideal tool for characterization of fuels ignition and combustion properties

Used for combustion experiments and research on new and reneable fuels

Flexible configuration with different injection systems and features available

Also available as Dual-fuel unit

The operating principle is to simulate the conditions in a reciprocating engine, however with a simplified approach, where the effects of engine dynamics (e.g. piston movement) are eliminated. This method makes it easier to isolate and study the effects of varying fuel properties and fuel compositions.

Technology

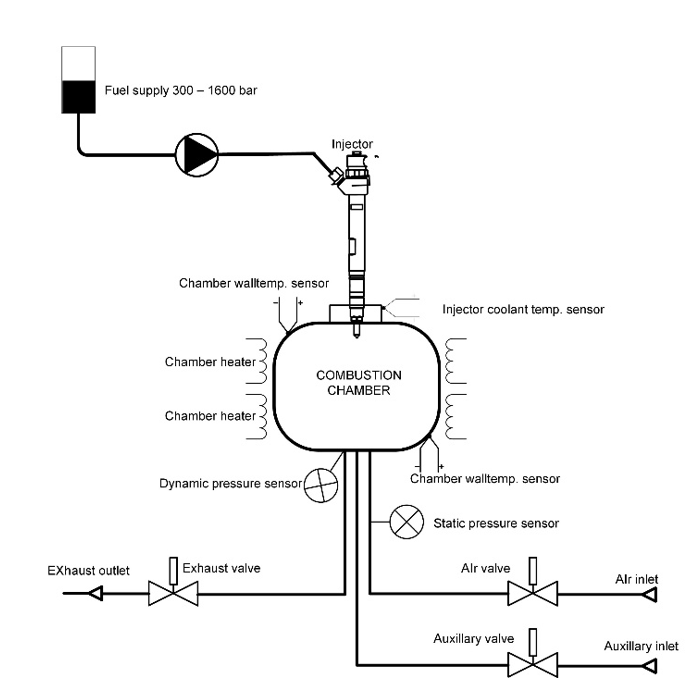

The CRU technology is based on a Constant Volume Combustion Chamber (CVCC) and a common rail type fuel injection system. Different engine loads and operating conditions can be simulated by varying the physical conditions.

The electrical heated combustion chamber and a common rail type injector ensures very good repeatability between each injection and combustion cycle.

Charge pressure and temperature can easily be adjusted without relation to each other.

Small fuel sample volume required.

Variable test conditions

Define a test matrix with up to 20 different physical conditions to be performed automatically

10 – 70 bar initial chamber pressure

300 -700°C chamber temperature

200 – 1400 bar fuel injection pressure

Variable injection duration

O2 dilution (EGR simulation).

Test results and output

During the combustion cycle, pressure development is logged with high frequency and resolution. From this set of data, numerous ignition and combustion parameters are derived and reported in a text file.

Pressure trace and Rate of Heat Release curve can be displayd in CRU software and exported to for instance MS. Excel.